-

Titanium Pipe Fittings

-

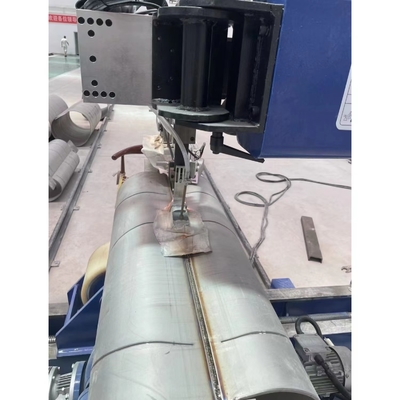

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

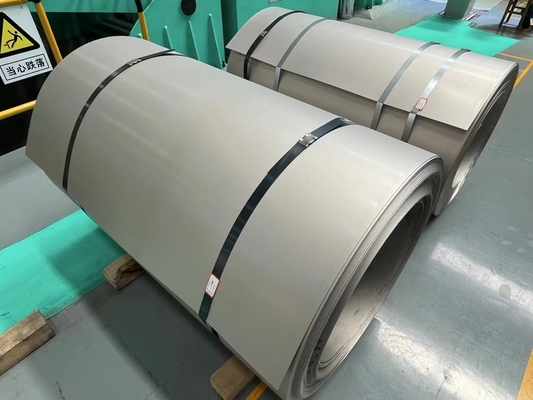

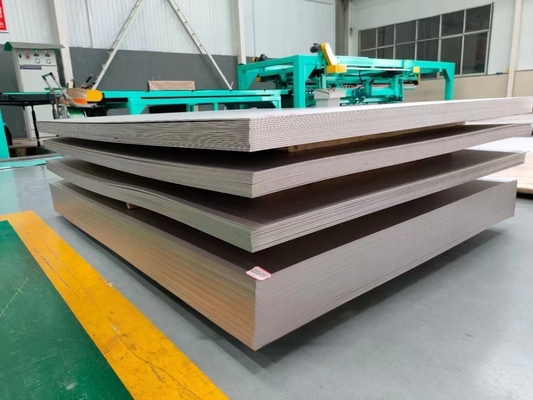

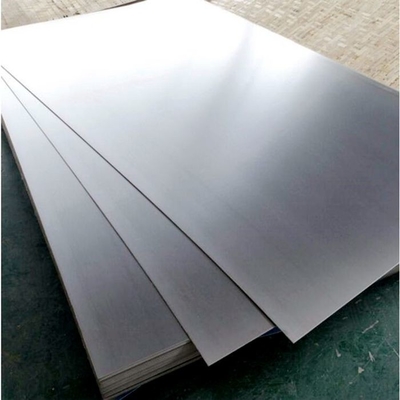

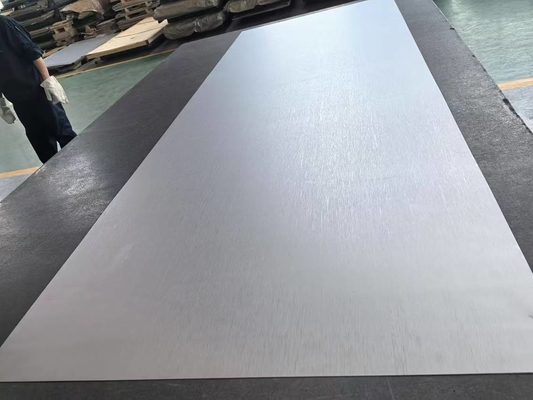

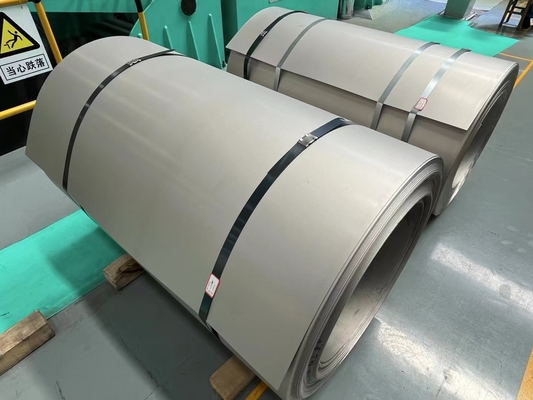

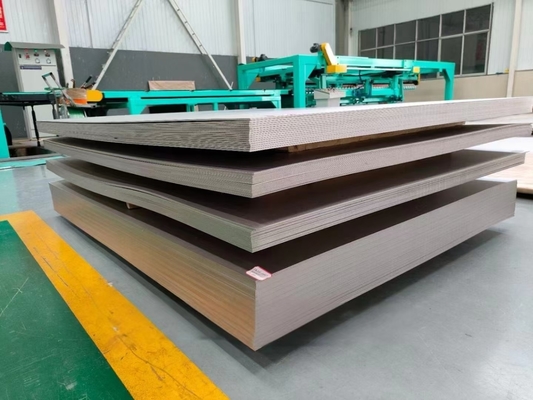

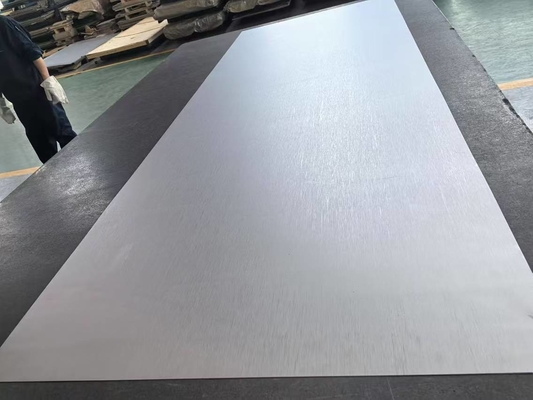

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Alloy Shell Gr5 Welded Shell For Torpedo Aerospace Chemical Industry

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001;2015 |

| Model Number | ASTM |

| Minimum Order Quantity | 50kg |

| Price | $15.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium Alloy | Application | Marine,Aerospace And Defensing |

|---|---|---|---|

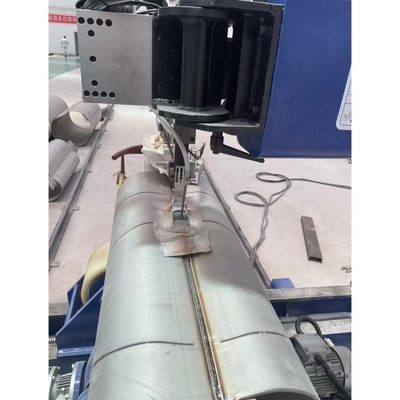

| Standard | AMS 4911/AMS 4900/AMS 4901/AMS 4902/AMS 4914 | Processing | CNC, Forge, Rolling And Welded |

| Origin | Baoji City, China | Other Grade | Titanium Gr5/TA10 |

| Stock | Titanium Gr1/2 Stock | Hardness | Generally In The Range Of 32-38 HRC |

| Yield Strength | 800 MPa | Others Mateiral | Titanium |

| Lengh | 2000-6000mm | Key Word | Ti 6Al4V Alloy Titanium Plates |

| Surface Process | Polished, Anodized, Sandblasted | Techique | Cold Rolled |

| Length | 100mm - 6000mm | Techinique | Cold Rolling Or Hot Rolling |

| Feature | High Elongation Rate | Technique | Cold Rolled |

| Thickness | 0.1mm - 10mm | ||

| Highlight | Marine Titanium Alloy Sheet Shell,Defending Titanium Alloy Sheet,AMS 4911 Titanium Alloy Plate |

||

Description

Titanium has strong acid and alkali corrosion resistance, and it will not rust when immersed in seawater for 5 years, while steel will corrode and deteriorate in seawater. Therefore, the outer shell of the ship is made of titanium alloy, and the seawater cannot corrode it. The submarine can resist both seawater corrosion and deep pressure, and its diving depth is 80% higher than that of stainless steel submarines. At the same time, titanium is non-magnetic and will not be detected by mines, so it has a good anti-monitoring effect. Generally, steel submarines will be easily crushed by water pressure when diving for more than 300m. The diving depth of titanium submarines exceeds 300m not only will it not be crushed, but also can effectively avoid the attack of depth charges, showing the unique charm and excellent performance of "titanium submarines". At present, titanium is an irreplaceable material for ships in the deep sea field. Russia successfully manufactured all-titanium submarines as early as 1968. Since the mid-1960s, Russia has produced 6 to 7 double-layer high-pressure hull "Alpha"-class all-titanium submarines and each submarine uses 3000t of titanium. In addition, such as "Shark"-class nuclear submarines, multi-purpose 945 and 988 nuclear submarines, etc., their underwater displacement is large, the underwater speed is fast, and the ultimate diving depth can reach 800m. Its pressure-resistant shell is made of titanium alloys. Titanium alloys are also widely used in torpedo launch tanks,Pumps, valves, pipes, propellers, etc. Made of titanium alloys on torpedo launch high-pressure gas cylinders and crisis coolers have good results and greatly extend their service life.

Grade:

Ti-6Al-4V

It is a titanium alloy strengthened by heat treatment, which has good weldability sheet formability and forging properties. Used in the manufacture of jet engine compressor blades, impellers, etc. Others such as landing gear wheels and structural parts, fasteners, brackets, aircraft accessories, frames, stringer structures, and pipes, are used in a wide variety of applications.

Ti-5Al-2.5Sn

The ability to resist cracks during forging is good, the formability is acceptable, the weldability is good, and the heat treatment cannot be strengthened. It is used for transmission gearbox casing, jet engine casing device and guide vane cover, pipeline structure, etc.

Ti-8Al-1Mo-1V

The formability and crack resistance during forging are acceptable, and the weldability is good, but it cannot be strengthened by heat treatment. Use the land to make jet engine blades, impellers and casings, gyroscope gimbal guide vanes, inner skins, and frames of nozzle devices

Ti-6A1-6V-2Sn

It is a dry heat-treatable strengthened titanium alloy with good crack resistance during forging, but poor weldability. Fabricate fasteners, and air inlet control guides, and test structural components from dry.

Ti-13V-11Cr-3A1

It is a heat-treatable and strengthened titanium alloy with good formability, certain crack resistance during forging, and acceptable weldability. It is used for structural forgings, plate stringer structures, skins, frames, brackets, aircraft accessories, and fasteners.

Ti-225A1-11Sn-5Zr-1Mo-0.2Si

It is a heat-treatable and reinforced titanium alloy with good crack resistance during forging.

Ti-6Al-2Sn-4Zr-2Mo

It has good formability and weldability and has good crack resistance during forging, but it is not strengthened by heat treatment. It is used to manufacture compressor blades, impellers, landing gear rollers, spacer compressor case assemblies, aircraft skeletons, skin components, etc.

Ti-4A1-3Mo-1V

It is a heat-treatable-strengthened titanium alloy with good forgeability and formability. Used in the manufacture of aircraft skeleton components.![]()

| Physical Properties | |||

| Grade | Tensile strength MPA | Yield strength MPA | Elongation % |

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

| Composition | |||||||||||

| Grade | Fe Max | O | N | C | H | Pd Max | Al | Va Max | Ni Max | Mo Max | |

| / | Wt % | Wt % | Wt % | Wt % | Wt % | Wt % | Wt % | Wt % | Wt % | Wt % | |

| Gr1 | 0.2 | 0.18 | 0.03 | 0.08 | 0.015 | ||||||

| Gr2 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | ||||||

| Gr4 | 0.5 | 0.4 | 0.05 | 0.08 | 0.015 | ||||||

| Gr5 | 0.4 | 0.2 | 0.05 | 0.08 | 0.015 | 5.5-6.7 | 3.5-4.5 | ||||

| Gr7 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12- 0.25 | |||||

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | 2.5-3.5 | 2.0-3.0 | ||||

| Gr12 | 0.3 | 0.25 | 0.03 | 0.08 | 0.015 | 0.6-0.9 | 0.2-0.4 | ||||

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | 5.5-6.5 | 3.5-4.5 | ||||

| Ti | Balance | ||||||||||

FRQ

Commercial CE SAA ROHS Certificate Outdoor IP65 Waterproof 20W 30W 50W 100W 200W 12V LED Flood Lights

Q1. Can I have a sample order for LED light?

A: Yes, we welcome sample orders to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparation,8-10 working days for mass production.

Q3. Do you have any MOQ limit for LED light orders?

A: Low MOQ, 1pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Ship by DHL, UPS, FedEx, or TNT. It takes 3-5 days to arrive. Airline and sea shipping are also optional.

Q5. How do I proceed with an order for LED light?

A: Firstly let us know your requirements or application.

Secondly, we will quote according to your requirements or our suggestions.

Thirdly, the customer confirms the samples and places a deposit for a formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on an LED light product?

A: Yes. Please inform us formally before our production.

Q7: Do you offer a guarantee for the products?

A: Yes, we offer 5 years warranty on our products.

Q8: How to deal with the faulty?

A: Firstly, Our products are produced in a strict quality control system and the defective rate will be less than 0.2%.

Secondly, during the guarantee period, we will send new lights with new orders for small quantities. For defective batch products, we will repair them and resend them to you or we can discuss the solution including re-call according to the real situation.