-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

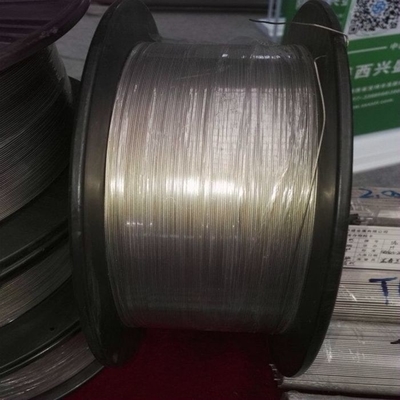

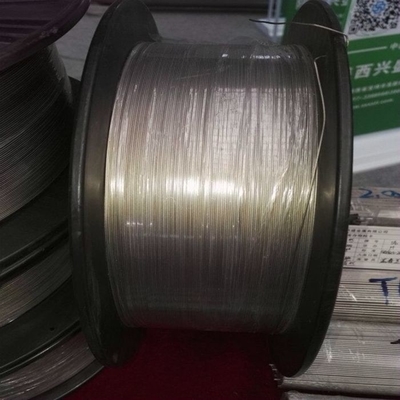

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Aerospace, Chemical Industry, Medical Equipment | Shape | Straisht, Coiled |

|---|---|---|---|

| Corrosion Resistance | Excellent | Rolling Process | Cold Rolling |

| Supply Form | In Coil, On Spool, In Straight Lengths | Using | SEATWATER |

| Color | Titanium Color | Supply State | Annealed |

| Highlight | Seawater Use Titanium Welding Wire,4.51g/cm3 Titanium Welding Wire |

||

Product Description:

The Titanium Welding Wire is manufactured using a cold rolling process, which ensures high strength and durability. This process also helps to eliminate any impurities and defects in the wire, resulting in a smooth and consistent welding experience. The wire gauge for this product is 2.0mm, which is suitable for a range of welding tasks.

Our Titanium Welding Wire is highly versatile and can be used for welding various materials, including aluminum alloys. It is also compatible with Hardfacing Flux Cored Welding Wires, making it an excellent choice for welding applications that require high strength and durability.

When it comes to delivery, we understand the importance of meeting deadlines. That's why we ensure that our Titanium Welding Wire is always available and can be delivered within 7-15 days of placing an order.

In summary, our Titanium Welding Wire is a reliable, high-quality product that delivers excellent welding results. Its titanium color, straight and coiled shapes, cold rolling process, and 2.0mm wire gauge make it suitable for a wide range of welding applications. Whether you're welding aluminum alloys or using Hardfacing Flux Cored Welding Wires, this welding wire is the perfect choice for your welding needs.

Features:

- Product Name: Titanium Welding Wire

-

Feature:

- High Strength

- Corrosion Resistance

- Density: 4.51 G/cm³

-

Application:

- Aerospace

- Chemical Industry

- Medical Equipment

- Rolling Process: Cold Rolling

- Using: SEATWATER

Other related products:

- Hardfacing Flux Cored Welding Wires

- High Temperature Alloy Wire

- High Temperature Alloy Wire

Technical Parameters:

| Strength | 950 |

| Density | 4.51 G/cm³ |

| Leading Time | 7-15days |

| Supply State | Annealed |

| Supply Form | In Coil, On Spool, In Straight Lengths |

| Color | Titanium Color |

| Surface Finish | Polished, Acid Washing |

| Corrosion Resistance | Excellent |

| Feature | High Strength, Corrosion Resistance |

| Rolling Process | Cold Rolling |

This table represents the technical parameters of a Titanium Welding Wire product. This product is known for its high strength and excellent corrosion resistance. It is available in annealed supply state and in various supply forms such as in coil, on spool, and in straight lengths. The surface finish of the product can be polished or acid washed. The product has a leading time of 7-15 days and has a density of 4.51 G/cm³. It has a titanium color and is made using cold rolling process.

In addition to Titanium Welding Wire, there are other types of welding wires available in the market such as Copper Nickel Alloy Wire, Johnson Wire Screen Welding Machine, and Flux Cored Arc Welding Wire.

Applications:

One of the primary applications for this product is in the aerospace industry. Here, it is used to weld titanium and aluminum alloy parts together, creating strong and reliable connections that are essential for safe and efficient flight. The wire's high strength and resistance to corrosion make it particularly well-suited to this application, as it can withstand the extreme conditions encountered during flight.

Another industry that can benefit from the use of the Titanium Welding Wire is the chemical industry. Here, the wire can be used to weld together a variety of different materials, including aluminum alloy welding wire and copper nickel alloy wire. These connections are essential for creating chemical processing equipment that is both durable and reliable, ensuring that the materials being processed are handled safely and efficiently.

Medical equipment is another area where the Titanium Welding Wire can be extremely useful. From surgical instruments to implantable medical devices, the wire's high strength and resistance to corrosion make it an ideal choice for creating these critical components. Its titanium color also makes it an aesthetically pleasing option for medical equipment, ensuring that it looks as good as it performs.

Regardless of the application, the Titanium Welding Wire is a highly effective and reliable product that can be trusted to perform even under the most demanding conditions. It is easy to use and provides consistently high-quality results, making it a valuable addition to any industrial setting. So whether you are using it to weld aluminum clad steel wire, copper nickel alloy wire, or any other material, you can be confident in the performance of the Titanium Welding Wire.

Using SEATWATER, the Titanium Welding Wire is designed to provide superior performance and reliability, ensuring that it can withstand even the harshest conditions. So if you need a high-quality titanium welding wire for your application, look no further than this versatile and durable product.

Customization:

Customize your Titanium Welding Wire with our product customization services:

- Leading Time: 7-15 days

- Color: Titanium Color

- Corrosion Resistance: Excellent

- Surface Finish: Polished, Acid Washing

- Supply Form: In Coil, On Spool, In Straight Lengths

Our customization services can help you tailor your Titanium Welding Wire to fit your specific needs. Whether you need a certain color or surface finish, we can help. Our product offers excellent corrosion resistance, making it a great choice for a variety of applications. We also offer Copper Nickel Alloy Wire and Copper Alloy Welding Wire, as well as Johnson Wire Screen Welding Machine. Contact us today to learn more about our customization services and how we can help you get the most out of your Titanium Welding Wire.