-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

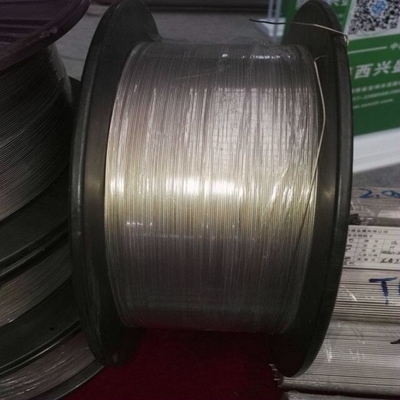

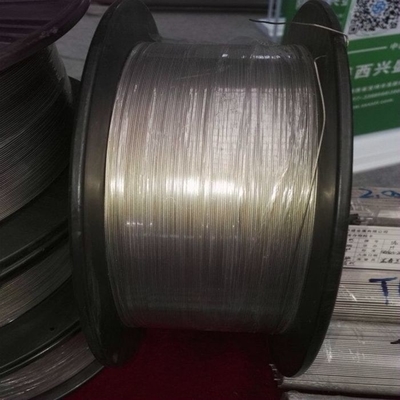

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface Finish | Polished, Acid Washing | Shape | Straisht, Coiled |

|---|---|---|---|

| Supply Form | In Coil, On Spool, In Straight Lengths | Material Grade | Grade5 |

| Rolling Process | Cold Rolling | Corrosion Resistance | Excellent |

| Density | 4.51 G/cm³ | Color | Titanium Color |

| Highlight | 5 Titanium Alloy Welding Wire |

||

Product Description:

Our Titanium Welding Wire is designed with a wire gauge of 2.0mm, ensuring that it is the perfect size for a variety of welding tasks. Additionally, this welding wire's high strength and corrosion resistance make it the perfect choice for high-temperature alloy wire, hardfacing flux cored welding wires, and Johnson wire screen welding machines.

This welding wire's high strength and excellent corrosion resistance make it perfect for use in a variety of industries, including aerospace, the chemical industry, and medical equipment. Whether you need a reliable welding wire for your aircraft or a product that can withstand harsh chemical environments, our Titanium Welding Wire is the perfect choice.

Our Titanium Welding Wire is manufactured to the highest quality standards, ensuring that it will perform flawlessly every time you use it. Whether you're a professional welder or a DIY enthusiast, you can trust our product to deliver exceptional performance and reliability.

In conclusion, if you need a welding wire that offers high strength, excellent corrosion resistance, and is perfect for high-temperature alloy wire, hardfacing flux cored welding wires, and Johnson wire screen welding machines, our Titanium Welding Wire is the perfect choice. So why wait? Order yours today and experience the difference for yourself.

Features:

- Product Name: Titanium Welding Wire

-

Application:

- Aerospace

- Chemical Industry

- Medical Equipment

-

Shape:

- Straight

- Coiled

-

Supply Form:

- In Coil

- On Spool

- In Straight Lengths

- Supply State: Annealed

- Leading Time: 7-15days

-

Other features:

- Can be used as Flux Cored Arc Welding Wire

- Suitable for welding Aluminum Alloy

- Can be used with Automatic Wire Mesh Welding Machine

Technical Parameters:

| Shape | Straight, Coiled |

| Surface Finish | Polished, Acid Washing |

| Wire Gauge | 2.0mm |

| Supply State | Annealed |

| Using | SEATWATER |

| Material Grade | Grade5 |

| Corrosion Resistance | Excellent |

| Feature | High Strength, Corrosion Resistance |

| Color | Titanium Color |

| Leading Time | 7-15 days |

Applications:

Customization:

- Corrosion Resistance: Excellent

- Wire Gauge: 2.0mm

- Surface Finish: Polished, Acid Washing

- Application: Aerospace, Chemical Industry, Medical Equipment

- Rolling Process: Cold Rolling

Our customization services allow you to tailor your Titanium Welding Wire to your specific needs. Whether you need it for galvanized welded wire mesh, hardfacing flux cored welding wires, or Johnson wire screen welding machine, we've got you covered. Contact us today to discuss your customization options!

Support and Services:

The Titanium Welding Wire is a high-quality welding wire that is designed for various welding applications. Our technical support team is always ready to assist with any inquiries regarding the product, including its features, properties, and applications. We also offer a range of services to ensure that our customers can fully utilize the product, including:

- Training and education on the proper handling and use of the welding wire

- Customized product recommendations based on specific welding needs

- On-site technical support for welding projects

- Quality testing and analysis of the welding wire

- Consultation services on welding processes and techniques

Our goal is to provide excellent technical support and services to our customers to ensure that they achieve the best results with our Titanium Welding Wire.