-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

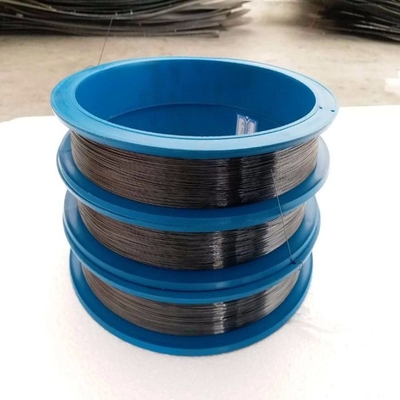

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Leading Time | 7-15days | Corrosion Resistance | Excellent |

|---|---|---|---|

| Wire Gauge | 2.0mm | Material Grade | Grade5 |

| Surface Finish | Polished, Acid Washing | Supply Form | In Coil, On Spool, In Straight Lengths |

| Rolling Process | Cold Rolling | Supply State | Annealed |

| Highlight | 2.0mm Diameter Aluminum Alloy Welding Wire,Acid Washed Aluminum Alloy Welding Wire,Grade 5 Aluminum Alloy Welding Wire |

||

Product Description:

One of the standout features of this welding wire is its high strength, which makes it ideal for use in applications where durability and reliability are critical. The wire's high strength also makes it an excellent option for use in automatic wire mesh welding machines, as well as Johnson wire screen welding machines.

In addition to its strength, the Titanium Welding Wire is also highly resistant to corrosion, which makes it an excellent choice for use in applications where the wire will be exposed to harsh or corrosive environments. Whether you are working on a project in a marine environment or in a chemical processing plant, this welding wire will help ensure that your welds remain strong and reliable over time.

The Titanium Welding Wire is available in a variety of supply forms, including in coil, on spool, and in straight lengths. This versatility makes it easy to find the perfect supply form for your specific welding needs, whether you are working on a large-scale project or a small, intricate welding job.

When ordering the Titanium Welding Wire, you can expect a leading time of 7-15 days. This fast turnaround time ensures that you can get started on your welding project as soon as possible, without having to wait around for your supplies to arrive.

Overall, the Titanium Welding Wire is an excellent choice for welders who need a high-strength, corrosion-resistant welding wire that is versatile and easy to use. Whether you are working on an automatic wire mesh welding machine or a Johnson wire screen welding machine, this welding wire will help ensure that your welds are strong, reliable, and long-lasting.

Features:

- Product Name: Titanium Welding Wire

- Material Grade: Grade5

- Feature: High Strength, Corrosion Resistance

- Supply State: Annealed

- Shape: Straight, Coiled

- Rolling Process: Cold Rolling

Our Titanium Welding Wire is perfect for use with Johnson Wire Screen Welding Machine. It is also a great alternative to Aluminum Alloy Welding Wire and Copper Nickel Alloy Wire due to its high strength and corrosion resistance features.

Technical Parameters:

| Using | SEATWATER |

| Feature | High Strength, Corrosion Resistance |

| Strength | 950 |

| Supply State | Annealed |

| Density | 4.51 G/cm³ |

| Leading Time | 7-15days |

| Wire Gauge | 2.0mm |

| Corrosion Resistance | Excellent |

| Surface Finish | Polished, Acid Washing |

| Material Grade | Grade5 |

| Using | SEATWATER |

| Feature | High Strength, Corrosion Resistance |

| Strength | 950 |

| Supply State | Annealed |

| Density | 4.51 G/cm³ |

| Leading Time | 7-15days |

| Wire Gauge | 2.0mm |

| Corrosion Resistance | Excellent |

| Surface Finish | Polished, Acid Washing |

| Material Grade | Grade5 |

| Using | Aluminium Clad Steel Wire, Flux Cored Arc Welding Wire, Automatic Wire Mesh Welding Machine |

Applications:

- Aerospace: The High Temperature Alloy Wire is suitable for use in the aerospace industry. Its high strength and corrosion-resistant properties make it suitable for use in the aerospace industry. The wire can be used in the production of aircraft parts, rocket engines, and other aerospace equipment.

- Chemical Industry: The Titanium Welding Wire is ideal for use in the chemical industry. It can be used in the production of chemical processing equipment, pipes, and tanks. Its corrosion-resistant property makes it ideal for use in harsh chemical environments.

- Medical Equipment: The Titanium Welding Wire is suitable for use in the production of medical equipment. Its corrosion-resistant property makes it ideal for use in the production of medical implants and prosthetics.

The Titanium Welding Wire can be used with Automatic Wire Mesh Welding Machine and Johnson Wire Screen Welding Machine. These machines can be used to produce wire mesh screens, which are used in a variety of applications. The wire can also be used in welding applications, where a strong and durable weld is required. Overall, the Titanium Welding Wire is a versatile product that can be used in a variety of applications.

Customization:

- Corrosion Resistance: Excellent

- Supply State: Annealed

- Using: SEATWATER

- Surface Finish: Polished, Acid Washing

- Application: Aerospace, Chemical Industry, Medical Equipment

We also offer customization services for other types of welding wire, including:

- Aluminum Alloy Welding Wire

- High Temperature Alloy Wire

- Aluminium Clad Steel Wire

Support and Services:

Our technical support team is always available to provide assistance with any questions or issues you may have with our Titanium Welding Wire. We offer a range of services, including:

- Expert advice on welding parameters and techniques

- Assistance with product selection and application

- Customized solutions to meet your specific welding needs

- Training and education on the use of our products

- Technical documentation and data sheets

Our commitment to customer satisfaction means that we strive to provide the highest level of support and service to all of our customers. Contact us today to learn more about our Titanium Welding Wire and how we can help you achieve your welding goals.